Engineering Applications of Honeycombs

Honeycombs have long been known to offer interesting properties, such as low mass-weight ratio, energy absorption, and mechanical and acoustic damping; but historically have been limited in geometry due to manufacturing constraints. Hexagonal honeycombs, like bees make, can be simply manufactured from sheets of material such as cardboard or aluminium. In contrast, triangle-based honeycombs are more difficult to manufacture, for example when used in rocket housings they are cut from large blocks of aluminium, which is wasteful and expensive.

Additive manufacturing (3D printing) makes it much easier to explore alternative geometries. Researchers in the School of Engineering and Innovation - Iestyn Jowers and Richard Moat - are exploring the properties and applications of honeycombs based on aperiodic patterns. Examples include the Penrose tilings, or the recently discovered hat and spectre monotilings. Aperiodic patterns have structure, but do not have translational repetition, and can be described by a small set of polygons which can be arranged so they leave no gaps and don’t overlap.

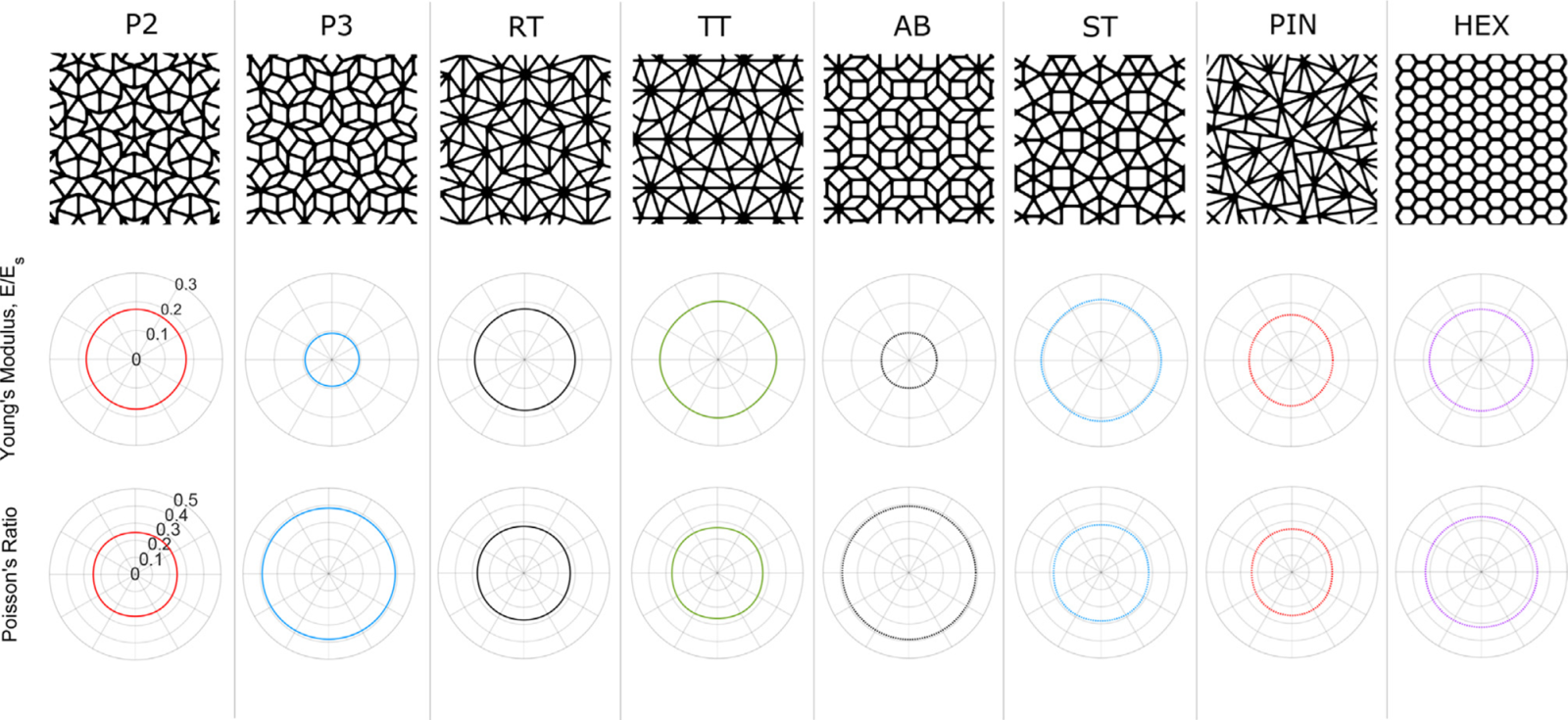

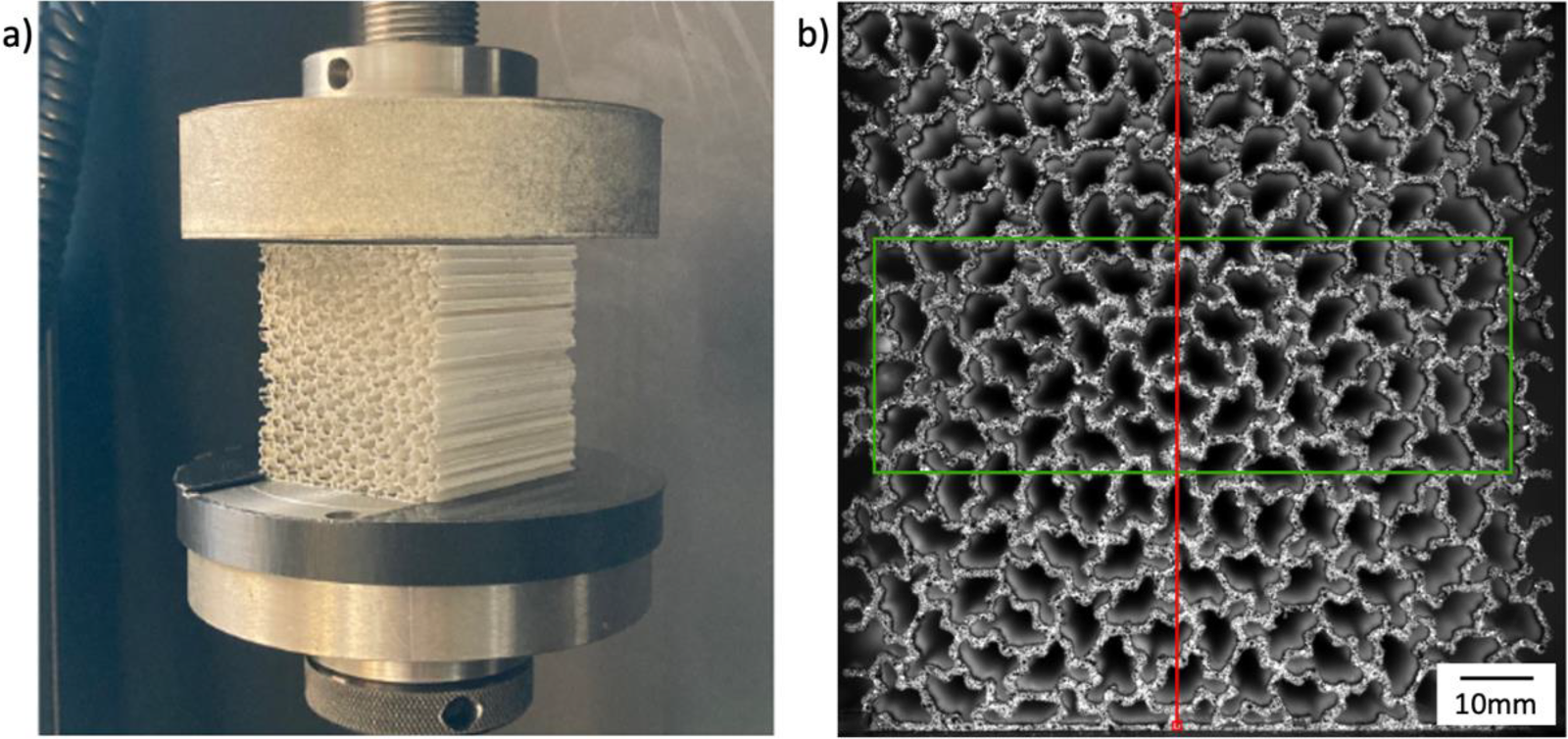

Using a combination of simulation and mechanical testing of additively-manufactured samples, the following discoveries have been made:

1. Honeycombs based on aperiodic patterns are mechanically isotropic

Future engineering applications will utilise the knowledge generated in these studies, which includes:

(a) Honeycombs with zero Poisson’s ratio could be useful where secondary deformation is not wanted; examples include aerospace (e.g. morphing wings) and medical devices (e.g. stents)

(b) Isotropic mechanical behaviour is useful in applications where the direction of applied force is not known; e.g. to absorb energy in crash barriers, helmets, armour

(c) Honeycombs with tuneable mechanical properties would be useful to interface between layers of different solid materials; e.g. to stop thermal shock or to reduce interference stresses due to uneven material expansion

Figure 1. Mechanical testing and porous structure of a 3D-printed honeycomb

Figure 2. Mechanical properties of various honeycomb structures

If you’d like to know more about how to apply creative and analytical knowledge to real world problems then check out our Engineering, Design and Innovation, and Environmental Management courses.